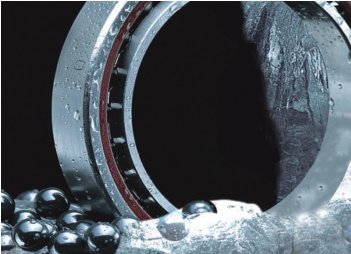

Keywords: spindle bearing, angular contact ball bearing, ball bearing, outer ring

The shaft parts of machine tools, especially the spindle bearings, are generally assembled into a body with thrust ball bearings, and rotate at a very high speed, sometimes producing very high heat. If this phenomenon is not eliminated in time, it will lead to overheating of angular contact ball bearings, and make the temperature of the corresponding parts of the machine tool rise and produce thermal deformation. In serious cases, the spindle and the tail frame will not be equal in height, which will not only affect the accuracy and processing accuracy of the machine tool itself but also burn the bearing.

Rated fatigue life refers to the total revolution of a group of bearings of the same type operating under the same conditions, in which 90% of angular contact ball bearings do not spall due to rolling fatigue. When the speed is constant, the rated fatigue life is expressed by the total running time.

When studying the life of thrust ball bearings, fatigue life should not be considered only, but also several service limits should be considered according to the performance of bearings. For example, the grease life of grease-lubricated bearings. Noise life, wear life, etc., according to different uses, the use limit benchmark is different, so most of the pre-selected experience limits.

Therefore, it is difficult to know the real cause of the damage only by investigating the damage of angular contact ball bearings. However, if we know the use of thrust ball bearing machinery, use conditions, the structure around the bearing, understand the situation before and after the accident, combined with the damage state of the bearing and several reasons, we can prevent similar accidents from happening again.

The availability of angular contact ball bearings is mainly determined by considering the degree of bearing damage, mechanical properties, importance, operating conditions and the period until the next overhaul. If the following defects can not be used, must be replaced with a new thrust ball bearing. There is a crack or notch on any one of the inner rings, outer ring, rolling body, or cage.

Wear failure is one of the common failure modes of bearings, which can be divided into common abrasive wear and adhesive wear.